Various Caster Size Options

August 30, 2019

Tradeshow Season 2020

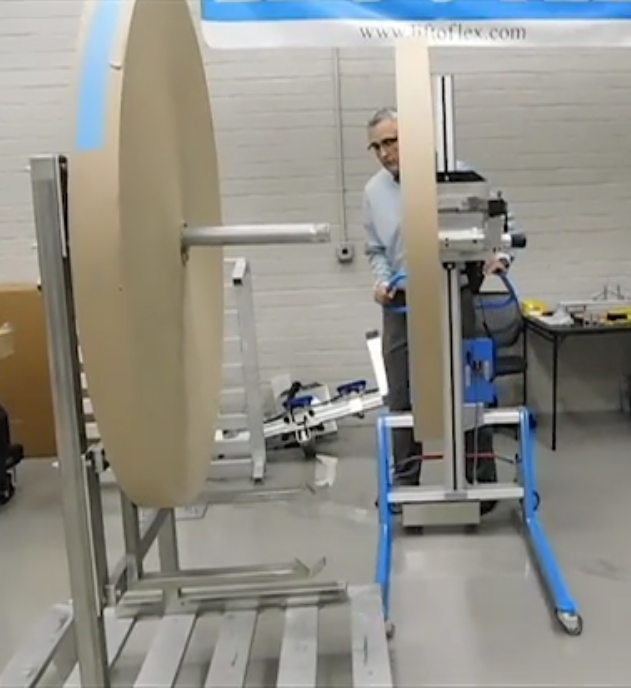

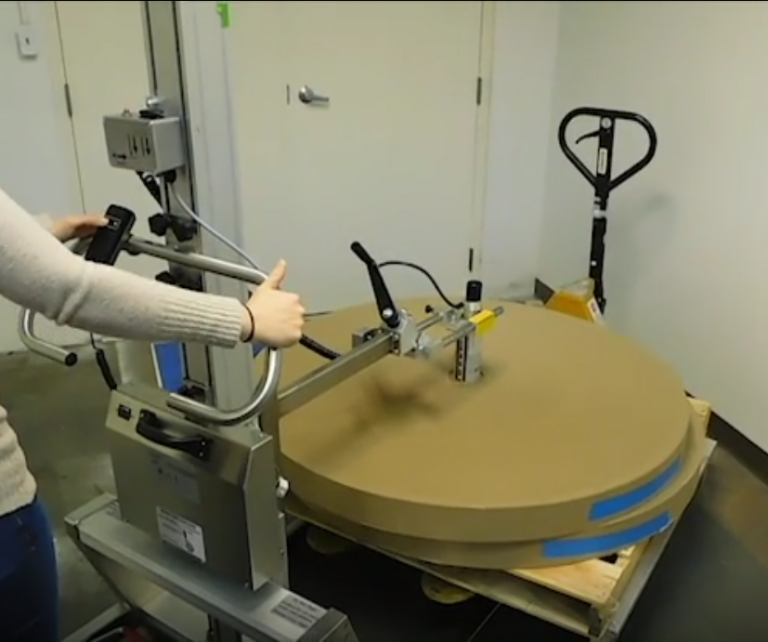

October 2, 2019The lifter shown below was a complex design. We used our standard 3″ Expand-O-Turn with a number of modifications. Our standard Expand-O-Turn grabs the interior of the roll core and rotates from core horizontal to core vertical (and vise versa) but the roll is always rotated so it can be passed off to a machine spindle on the right side of the lifter. The customer below had two rows of machines lined up with a very narrow hallway between both rows. The hallway was so narrow our lifter could not turn around between the rows of machines. That being said, we needed to further customize the lifter so once the rolls were rotated they could be passed off to a machine spindle located on either side of the lifter. In order to accomplish this, engineering had to remove our standard set of roller bars on our tooling and replace the channel with a strip of solid steel to aid in pushing the rolls onto the machine spindles located to the left side of our lifter.

This particular lifter model is provided with our Expand-O-Turn end-effector used to handle rolls 52″ x 3″ core x 3″ width with a maximum weight of 220-lbs. The end-effector is being used to pick up rolls with their cores vertical and rotate them either to the right or left so that the cores are horizontal for ultimate insertion of the roll to the customers’ machine. Centerline of spindle drop off height to floor is not to exceed 48″.

Check out the photos below for more details: