Happy Holidays from R on I!

December 15, 2016

PROMAT 2017

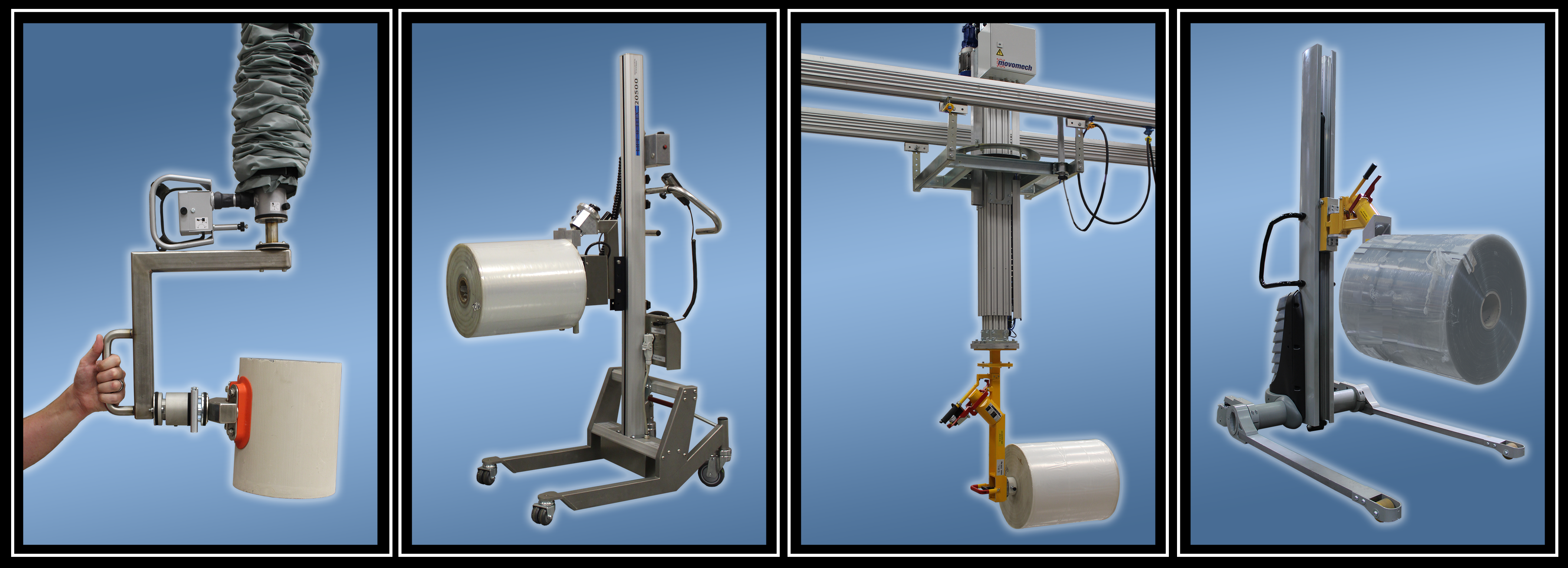

April 11, 2017Lifting and manipulating rolls of all types of material is a common problem within the material handling industry. We have a variety of solutions available to help with this problem. We can lift rolls of all types with different materials such as film, paper, plastic, foil, aluminum, textiles, as well as fabricated cylinders. We have helped all types of industries including aerospace, agriculture, chemical, construction, electronics, automotive, and food and beverage.

![]()

While some companies use roll carts and roll dollies to to lift and move their heavy rolls, we accomplish this with our portable electric roll handling lifters. They operate via an electric battery-powered system that allows the operator to lift, lower, clamp, and rotate heavy rolls of paper and film with the simple touch of a button on a handheld pendant or joystick. Eliminate the need for multiple people bending with their backs to manually manipulate rolls. Say goodbye to overexertion injuries and hello to reduced physical labor costs.

Your employees will thank you!

Most roll handling applications fall into one of the following three categories for attachments or end effectors.

Core Expander

With core expander applications, we use our tooling called Expand-O-Turn to grip the core of a roll. The actual grip action can be mechanical, electric, or pneumatic. We have different tools for each, depending on the specifics of the application. Common core sizes are 3 and 6 inches but we can also work with cores up to 10 inches. We can lift weight capacities up to 500 pounds, depending on the configuration of the equipment.

- Mechanical

- Electric

- Pneumatic

OD Gripper (outside dimension)

We can also grip a roll from the outside in the event we cannot insert an expander into the core. This is accomplished with electric powered squeeze arms with V-Blocks that we call our Squeeze-O-Turn tooling. It is simple to use and designed to not damage the product. It comes standard with a 12 inch stroke with an optional 20 inch stroke available. The squeeze arms can be mechanically adjusted to fit larger or smaller loads. We can lift weight capacities up to 300 pounds, depending on the configuration of the equipment.

- Squeeze-O-Turn with Rotating V-Blocks

- Squeeze-O-Turn

Adjustable Forks

A third potential solution for your roll handling needs is our Adjustable Fork Attachment. This is commonly used for cross roll handling and allows the operator to manipulate rolls from a pallet to a machine without the need for fixed or auxiliary equipment. The machine mandrel is used for horizontal pickup and drop off. The mandrel is inserted into the roll core with the adjustable forks on the lifter aligned for proper width. The lifter is moved into position and the roll is raised to the proper elevation for drop off. We can lift weight capacities up to 500 pounds, depending on the configuration of the equipment.

- Cross Roll Handling