Pack Expo Las Vegas, 2019

October 8, 2019

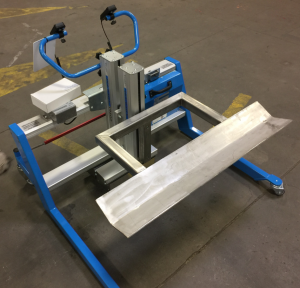

Core Probe with Adjuster Knob

November 18, 2019The customer featured in this case study, located in the southern suburbs of Illinois, is a worldwide specialty coated film company that designs, manufactures, and markets chemically complex multi-layer transferable coatings, foils, laminates and films.

The challenge in this scenario was maintenance related. The customer was having trouble accessing one of their machine rollers from a confined space inside their machine. The key design requirements for this project included two parts:

- We had to access an extremely low height inside the customer’s machine of 37.7” from the ground.

- We had to lift a 350 lb roll with a special rubber covering around it which could not be damaged.

RonI provided a solution using our 19000 portable lifter model incorporating a long v-block end effector for cross roll handling. The outside width of the v-block was 40” and had a distance of 14.5” from the face of the mounting tube to the center of the v-block.

The customer’s machine roller specks were: 10” diameter; 48” width; 350 lbs

Our lift mast was only 30.9” off the ground to enable access inside the machine. The v-block end effector design was strong enough to safely support the customer’s machine roller yet gentle enough to not damage anything.

The low mast enabled the lifter to be pushed inside the machine where it could be placed under the roller for removal with the v-block end effector all while occupying a very small footprint.