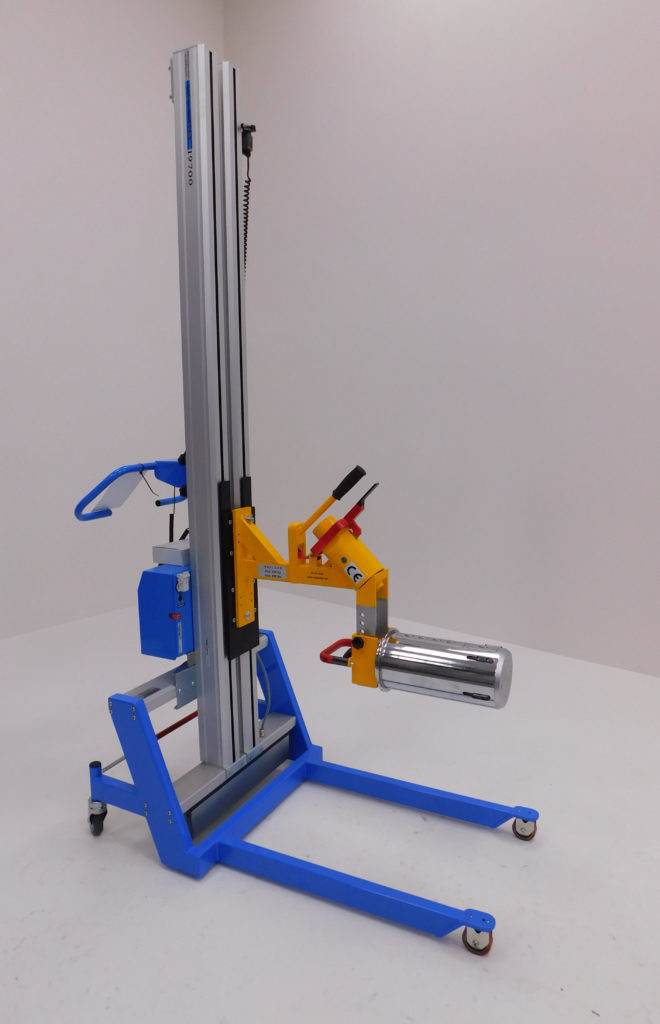

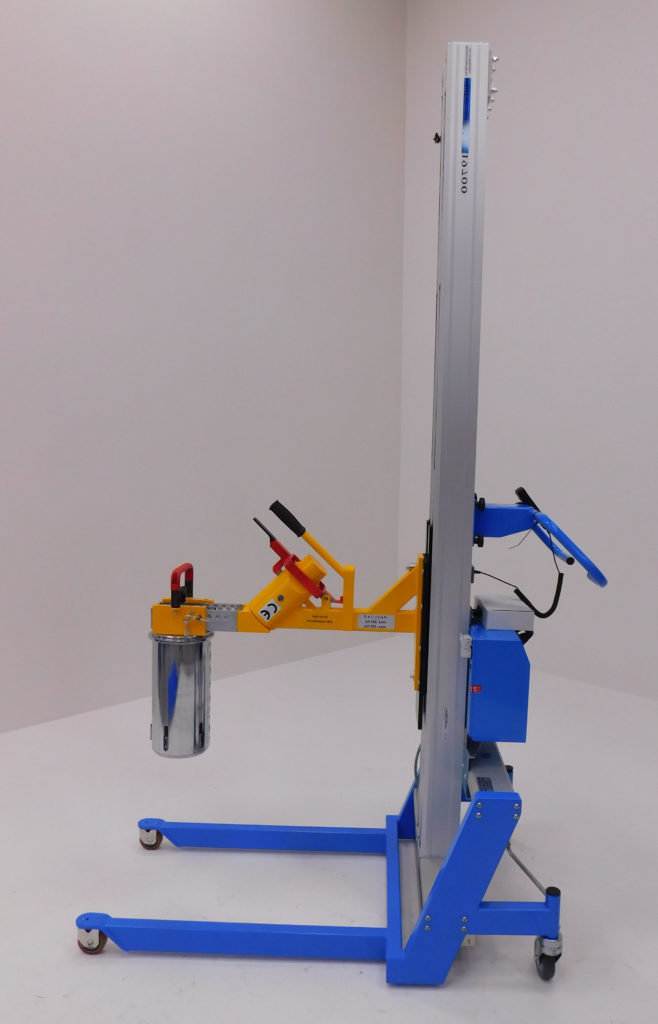

Lift-O-Turn with Brute Drum Arms

July 23, 2021

Drum Handling with our Swivel Hook

August 31, 2021What exactly is Rolling Handling with a Double Ju? Rolls can be gripped by the inner core -or- outer core depending on a number of factors. The type of lifter a customer receives depends on the size of the roll the lifter is interacting with. This particular customer wanted to lift three rolls at a time that were 40″ – 50″ inches in diameter x 5.25″ in width x 450 total pounds. Due to the size of this project we went with our Double Ju roll handling tooling. This specific tooling is 13″ long allowing for three rolls to be gripped at once, as well as, safely rotating from core vertical to core horizontal.

The operator, when in need of a roll, obtains a lifter and manually directs it to a pallet of rolls located in the staging queue. Shipper pallets are required to be placed onto an aluminum workstation pallet to allow for lifter leg access.

Once in place, the operator lowers the end-effector to the proper position inside the core and stops the end-effector. This action will grip the core, holding the roll in position during transport. After gripping, the operator raises the end-effector, moves the lifter away from the pickup point and rotates the roll manually. After rotation, the operator can then move the roll to the machine in need of the roll.

Next, the operator raises or lowers the end-effector to the proper height aligning the roll core with the spindle. After alignment, the operator manually releases the core and then off loads the roll. After offloading, the operator then moves the lifter back to its waiting position to await the next transport.

Click HERE to see our portable lifter line options, as well as, HERE to find additional details about our Cranes and Manipulators product line.

Take a Closer Look at our Roll Handling with our Double Ju:

What’s Going On At RonI…

Recent Blog Posts:

Upcoming + Future Tradeshow Events

Interested In Leaving A Comment?

We would love to hear your thoughts regarding this blog. Scroll down below and tell us what you think!