Case Study – Lift-N-Glide

August 15, 2019

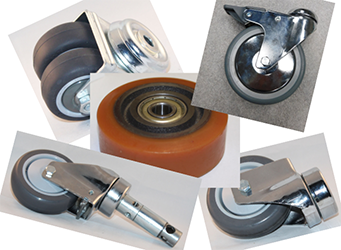

Various Caster Size Options

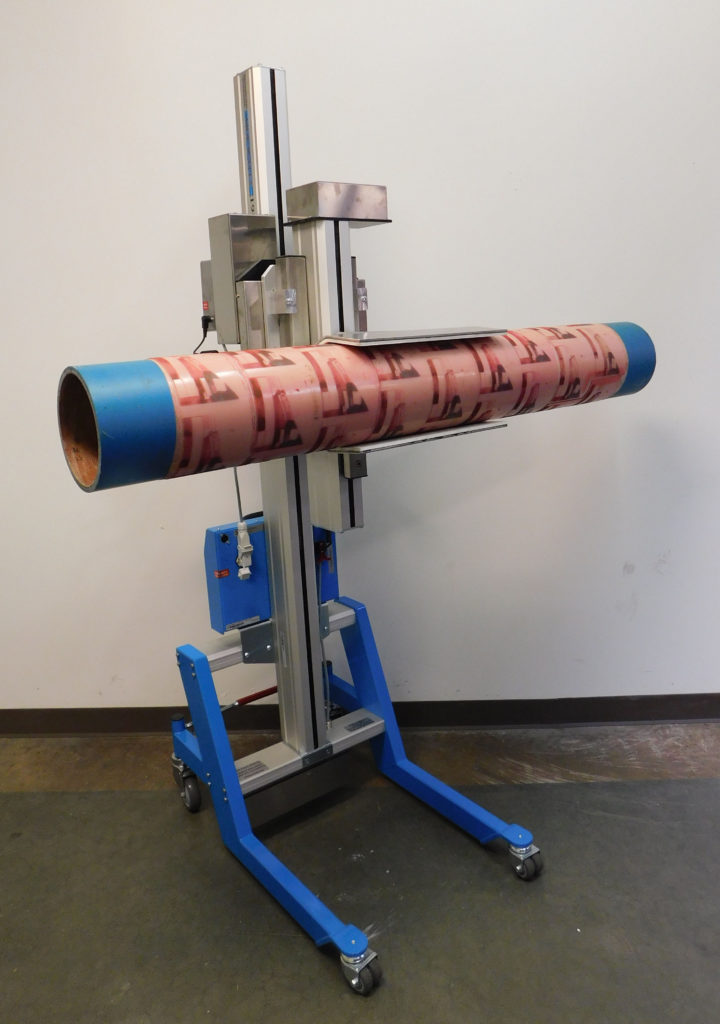

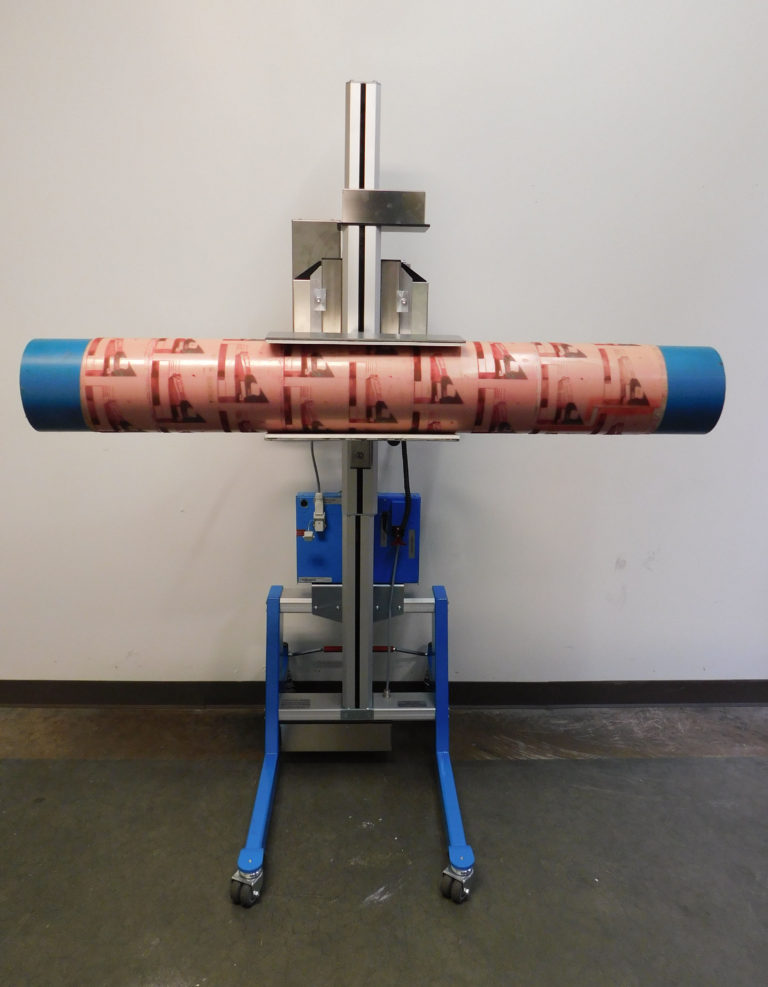

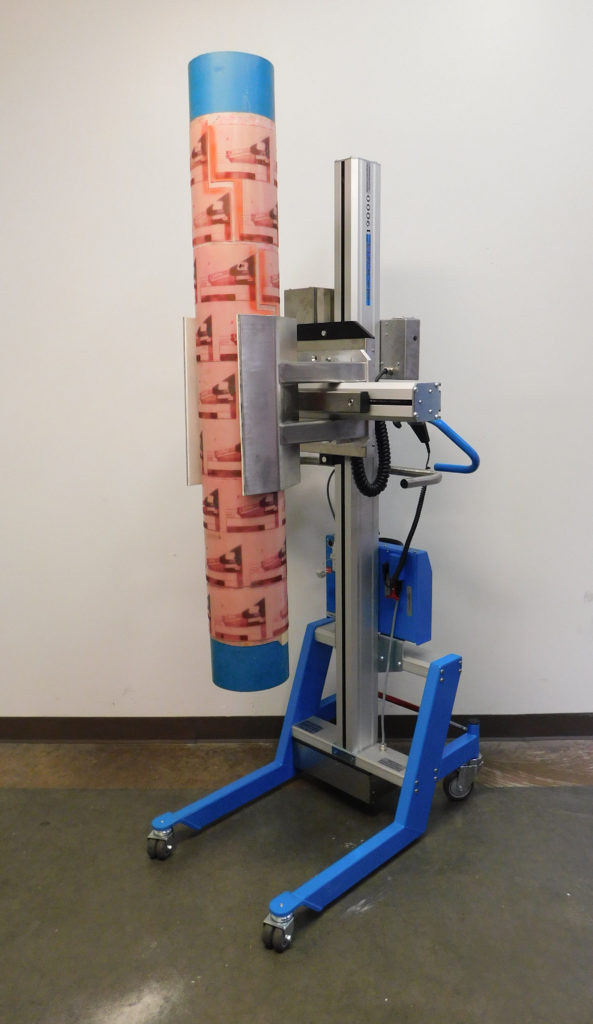

August 30, 2019This lifter is used within the Paper Manufacturing Industry in one of the print sleeve rooms. This particular facility had multiple uses for our lifters. The various requests are shown below.

- Pick up the print sleeves with their cores horizontal from a machine spindle and rotate the sleeves so the cores are vertical for placement onto their stationary storage racking system.

- Pick up the print sleeves with their cores vertical from the storage racking system and rotate the sleeves so the cores are horizontal for placement onto their machine spindles.

- Pick up the print sleeves with their cores vertical from the storage racking system and rotate the sleeves so the cores are horizontal for placement onto their portable rolling racks.

This particular lifter model is provided with our Squeeze-O-Turn end-effector used to handle print sleeves, 16-14.25” diameter x 67” wide, a maximum weight of 100-lbs, with a maximum lift of 64″.

Regarding scenario #1 above:

The operator, when in need of a sleeve, obtains a lifter and manually directs it to the machine spindle. Once in place, the operator lowers or raises the end-effector to the proper position centering the gripper arms around the sleeve. Next, the operator then actuates the end-effector. This action will squeeze the sleeve, holding it in position. After actuation, the operator moves the lifter away from the pickup point and rotates the sleeve 90°. Next, the operator raises or lowers the end-effector to the proper height and then off loads the sleeve onto stationary storage racking system.

Regarding scenarios #2 & #3 above:

The operator, when in need of a sleeve, obtains a lifter and manually directs it to the sleeve storage racking system. Once in place, the operator lowers or raises the end-effector to the proper position centering the gripper arms around the sleeve. Next, the operator then actuates the end-effector. This action will squeeze the sleeve, holding it in position. After actuation, the operator electronically tilts the sleeve while moving the lifter at the same time to remove the sleeve from the storage rack. The operator then moves the lifter away from the pickup point and rotates the sleeve 90°. Next, the operator raises or lowers the end-effector to the proper height and then off loads the sleeve onto the machine spindles OR portable rolling racks.

Check out the photos below for more details: