PROMAT Trade Show, 2023

January 23, 2023

World of Concrete, Recap, 2023

January 26, 2023Reels can come with cores, wood casings, and more. A lot of times we cannot directly squeeze the product due to its sensitivity. In these cases, when there is a core, we can grip through the center of the core.

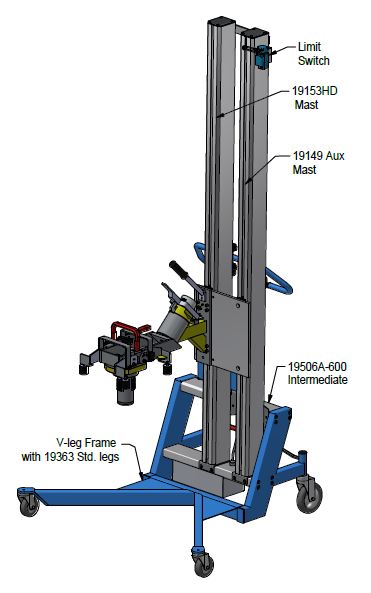

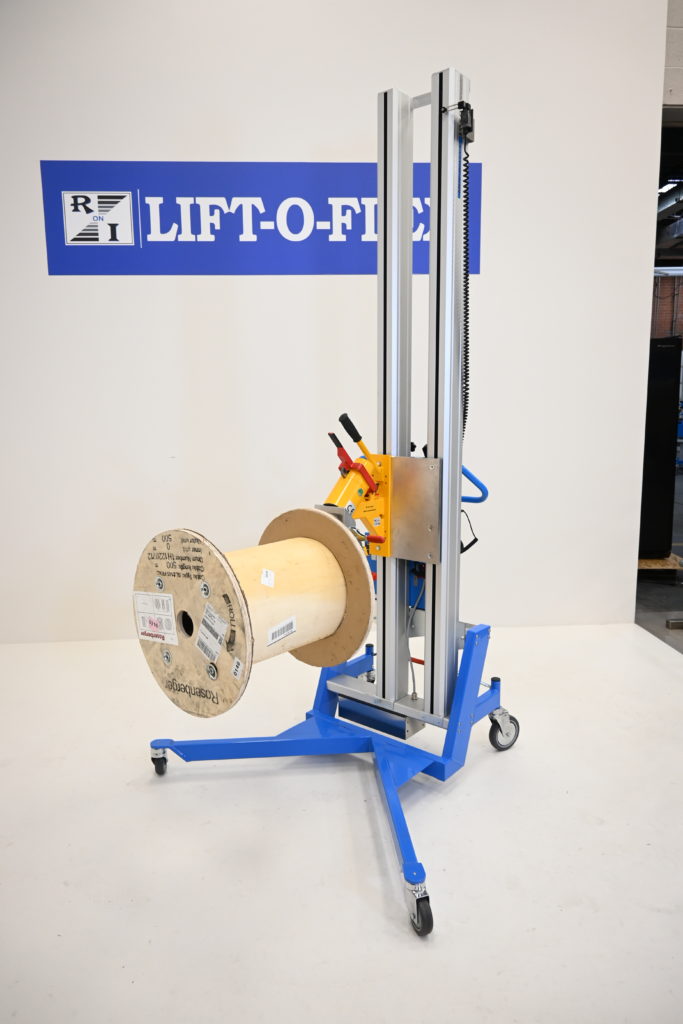

In the example below, we recommended our 19500S lifter model with our Double Ju tooling. This configuration enables the customer to pick up the reels sitting in core vertical position on a pallet and rotate them to core horizontal position on a cart. We also incorporated our V-lifter legs so the customer could move around each corner of their wooden pallets.

Product Reel Specs:

- 21″ Diameter

- 21″ Wide

- 350 lbs Max

Regarding this particular lifter, when the operator is in need of product, they take the lifter handle bars and manually push it to the storage rack of product located in the staging queue. The operator would position the lifter, while lowering the Double Ju expander with the remote control, so it is directly over the next available spool (being stored in core vertical position).

The gripper will be lowered until it is aligned in front of the reel core’s inner core. The operator would then guide the expander into the core and pull the lever to lower and lock the (4) rubber pads to provide pressure on the end caps. The operator would then raise the tooling and reel off the pallet.

Once clear of the pallet, the operator would manually rotate the reel to core horizontal position by pulling a locking lever and rotating the reel. The operator would then wheel the lifter to the drop-off cart. Once there, the reel can be lowered onto the cart and the expander can be retracted.

Once complete, the operator would pull the lifter back and wheel it to the staging queue for the next load.

Click HERE to see our portable lifter line options, as well as, HERE to find additional details about our Cranes and Manipulators product line.

Take a Closer Look at our Reel Handling Equipment:

See Our Reel Handling in Action:

What’s Going On At RonI…

Recent Blog Posts:

Upcoming + Future Tradeshow Events

Interested In Leaving A Comment?

We would love to hear your thoughts regarding this blog. Scroll down below and tell us what you think!