RonI Goes Solar!

November 21, 2022

PROMAT Trade Show, 2023

January 23, 2023What is Equipment Tray Lifting? Half of our business consists of custom projects that we design our lifters around. The below example was no exception. This particular customer needed to lift a stack of equipment trays and keep them secured (regardless of stack height) while moving them around their warehouse.

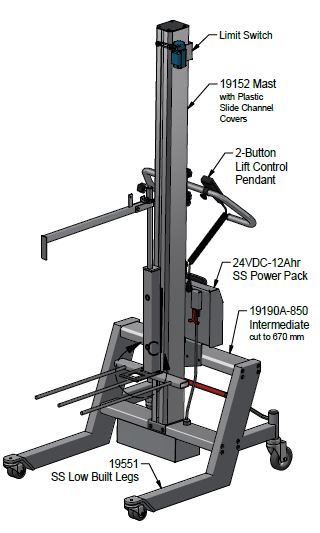

In this scenario, our team proposed our 19000 series stainless steel lifter model, along with custom fixed forks and a mounting post extension arm. The custom fixed forks were designed to fit into the notches on the bottom of the equipment trays so they would not slide from side to side on the lifter. The extension arm slides up and down on the mounting post which enables it to rest on top of the top equipment tray regardless of how many are stacked onto the fixed forks. The front of the extension arm has a tab which secures the load from falling forwards off of the forks. Our team also added a detent pin when the extension arm needs to be secured out of the way so the equipment trays can be offloaded in a safe manner.

Equipment Tray Lifting Specs:

- (3) holes on the bottom of each tray 1/2″ diameter

- From outside tray edge to center = 7.6″

- From outside tray holes to center = 5.2″

- Tray A = 1/2 stack = 21 trays = 50 lbs

- Tray B = 1/2 stack = 19 trays = 60 lbs

- Extension arm max height = 59.6″

- Extension arm max height (inverted) = +26.1″

Regarding this particular lifter, when the operator is in need of product, they take the lifter handle bars and manually push it to the storage rack of product located in the staging queue. The operator would position the lifter, while lowering the fixed forks with the remote control, so it is directly next to the equipment trays. The trays would be slid into position on the forks and they would be secured with the extension arm. Once the equipment trays are secured the operator would lift the fixed forks with the lifter remote control.

The operator would then wheel the lifter to the offloading location. Here, the operator would drive the tooling to be aligned with the offloading height and push the lifter so it’s resting next to the offloading location. Finally, the operator would raise the extension arm and secure it into place with the detent pin. Now the operator can slide the trays off of the fixed forks so the trays can be deposited to their final location.

Once complete, the operator would pull the lifter back and wheel it to the staging queue for the next load.

Click HERE to see our portable lifter line options, as well as, HERE to find additional details about our Cranes and Manipulators product line.

Take a Closer Look at our Equipment Tray Lifting:

What’s Going On At RonI…

Recent Blog Posts:

Upcoming + Future Tradeshow Events

Interested In Leaving A Comment?

We would love to hear your thoughts regarding this blog. Scroll down below and tell us what you think!